General Information About Mist Eliminators

Mist Eliminators

Types of mist eliminators

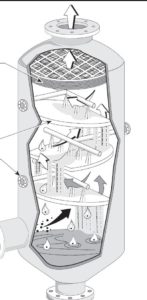

The types of mist eliminators include; wire mesh mist eliminators, fibre bed mist eliminators, and baffle-type.

• Wire-mesh mist eliminators – These are the most common mist eliminator in the market, as they remove entrained liquid droplets from streams of gas. They are made of knitted metal mesh and commonly used in vertical flows.

• Fibre-bed mist eliminators – This one consists of fibrous material arranged in columns. These materials remove mist from gas streams as the gas goes through them. The fiber bed mist eliminators are the most efficient and always remove very fine droplets of liquid found in a stream of gas.

• Baffle-type – This one is also called the chevron or vane. It alters the direction of the gas flow, with the aim of making the liquid droplets to collect on the baffle surface. It is efficient and effective for both horizontal and vertical gas flow systems.

How mist eliminators work

The mist eliminator performs its function in a simple, unique way. First of all, it captures the liquid droplets that may be present in a system. After capturing the droplets, it gets rid of them by draining them effectively.

Benefits of using mist eliminators

The first benefit is that it helps an organization to prevent maintenance costs of its systems and machines. This is because it effectively eliminates the water droplets that may be harmful to the machines and systems. Another benefit originates from its function. It ensures that no liquid droplets pass through the system to cause malfunctions of the system. They are also cost saving and will keep the operation costs as low as possible.

The first benefit is that it helps an organization to prevent maintenance costs of its systems and machines. This is because it effectively eliminates the water droplets that may be harmful to the machines and systems. Another benefit originates from its function. It ensures that no liquid droplets pass through the system to cause malfunctions of the system. They are also cost saving and will keep the operation costs as low as possible.

Conclusion

Mist eliminators always ensure that processes in any system run smoothly, effectively and efficiently. Many companies or organizations that use heavy machinery should employ the services of mist eliminators for cost reduction and increased productivity.

…